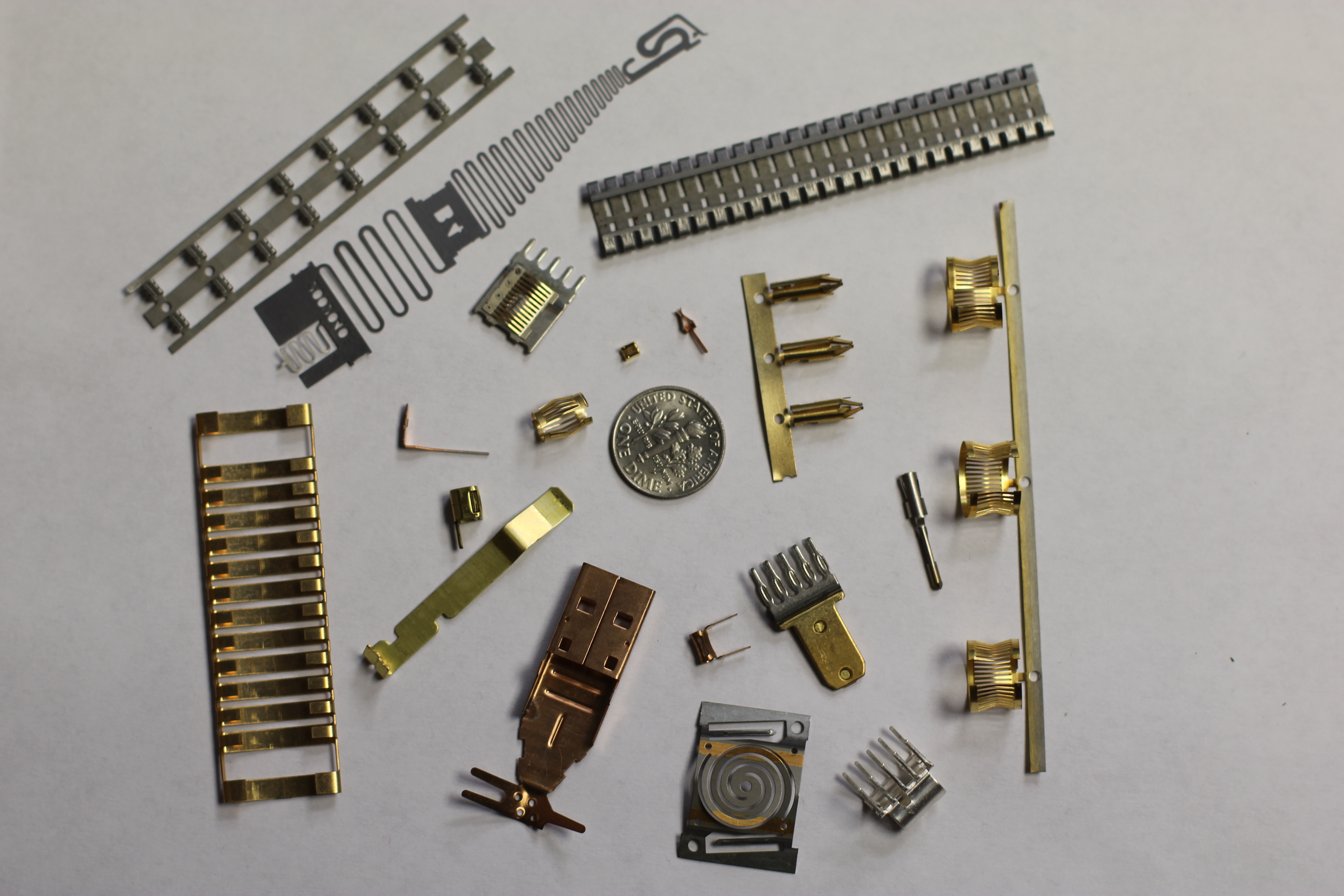

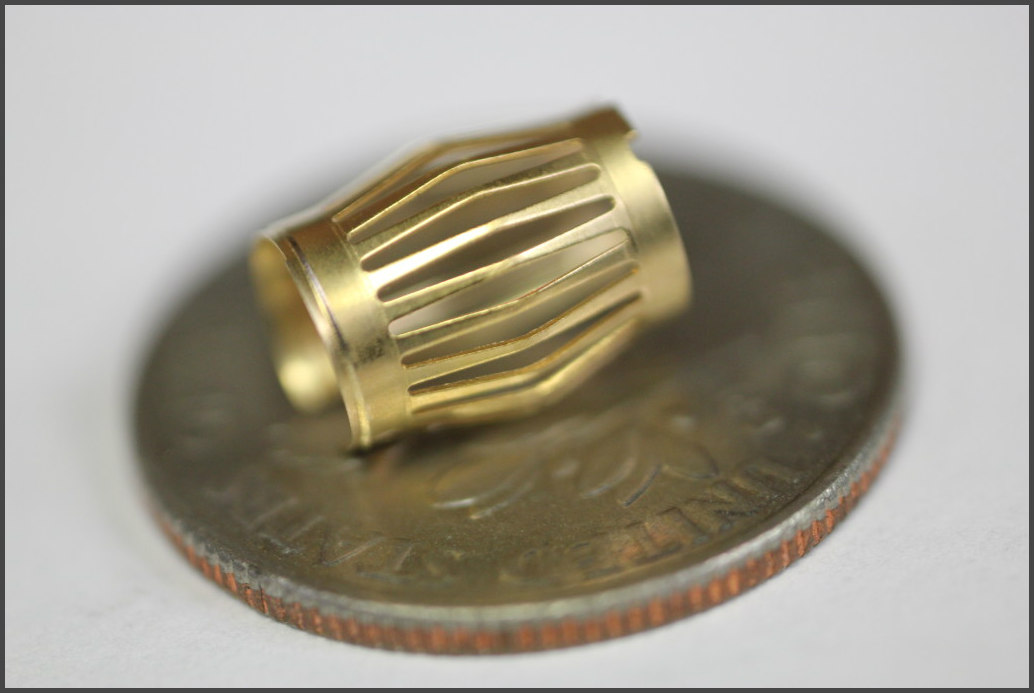

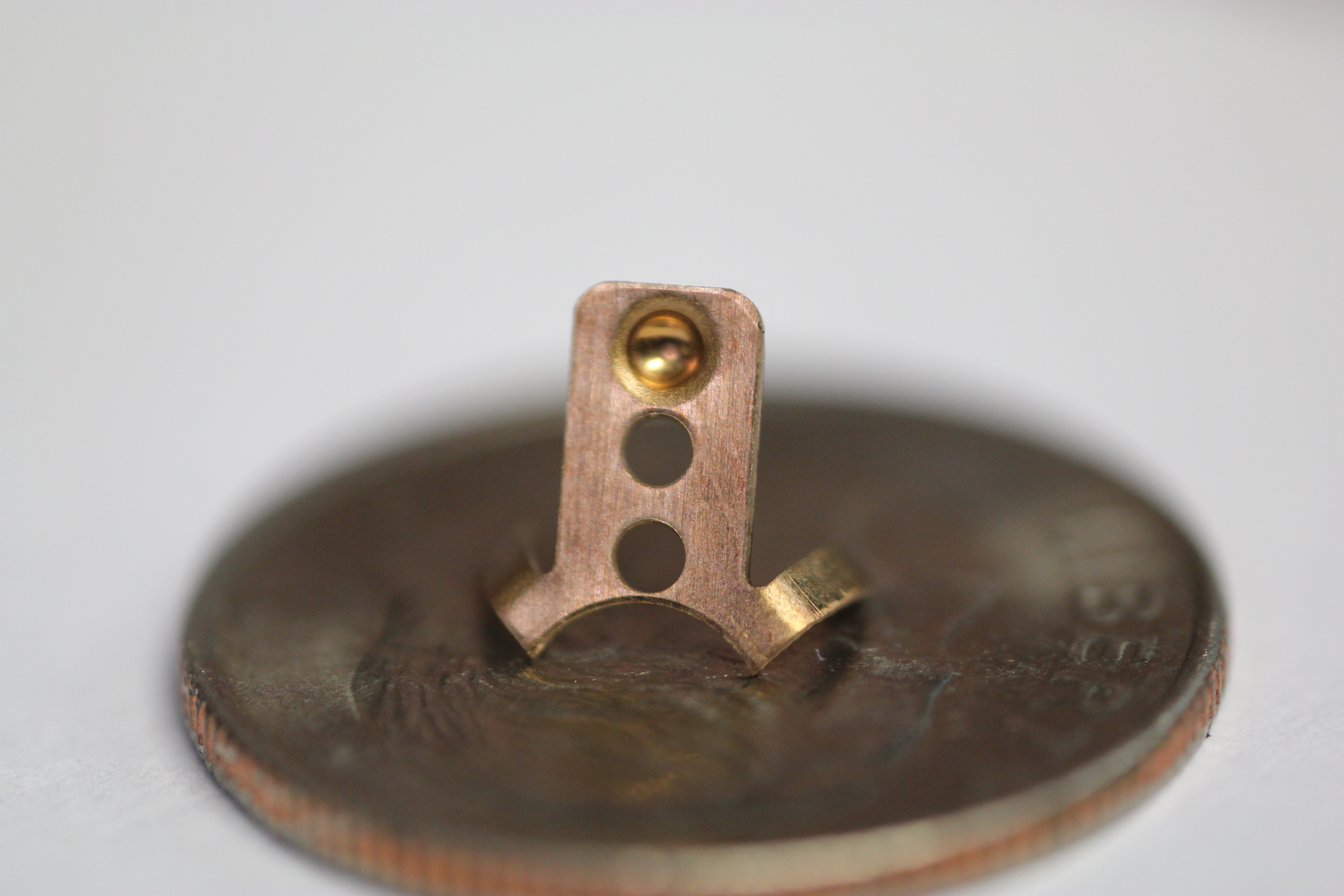

Toolander Engineering Inc. is a family owned and run business spanning three generations of highly experienced and disciplined Tool and Die Makers. Our expertise is in designing, building and operating complex tight tolerance precision stamping dies. To do this with excellence we are relentless in deeply understanding what is needed to create and stamp high quality parts. This deep understanding combined with our timeless craftsmanship approach and smart integration of new technologies makes us best in class. We pride ourselves on working side by side with our customers to help improve manufacturability and design creation, as well as keeping a keen focus on optimizing costs without compromising quality. In the end, our approach and process delivers the best possible product.

-

- ISO 9001:2015 Certified, DFARS & ROHS Compliant.

- Stamping quantites from a few thousand to multimillions.

- Precision stamping dies for custom components.

- No cost maintenance on tooling built and run by Toolander.

- Competitive pricing.

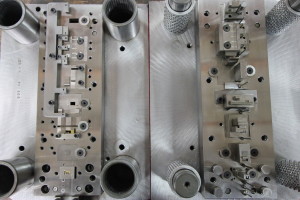

We design, build and run progressive dies for light gauge tight tolerance parts. Read more>>

All tooling is designed and produced in house giving us precise control over quality and keeping cost low. Read more>>

Is your product still in the design process? We can help you design your parts from scratch. Read more>>

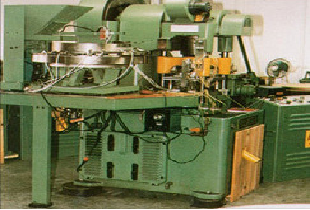

Automated Machines

The team at Toolander Engineering can design and build automated equipment. Read more>>

We have over 40 years experience in producing complex tight tolerance prototypes with short lead times. Read more>>

Toolander Engineering can take your stamped metal parts through many secondary operations and assemblies to a finished product. Read more>>